Super Dumbbell Die cutter – Precision & Efficiency

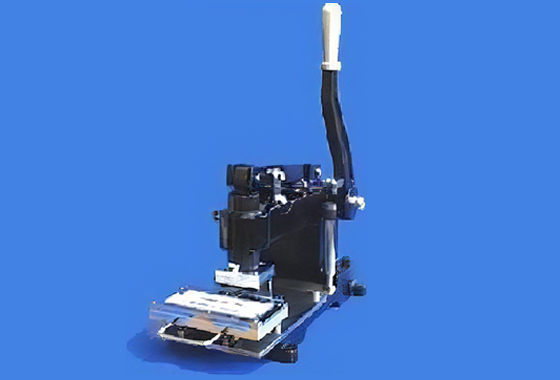

SD Type Lever-Controlled Sample Cutter Model : SDL-100

SD Type Lever-Controlled Sample Cutter Model : SDL-200

Multipurpose Test Specimens Cutter Model SDL-200-1AJ

Slitting Jig Vulcanized Rubber Tear Test Specimen Model SDSC-1200 Series

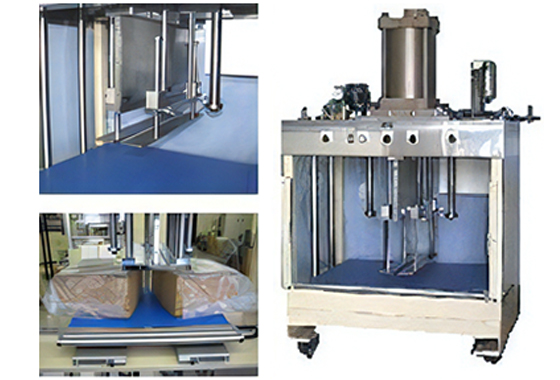

Heating / Cooling 2-stage 20ton automatic forming press machine MODEL SDOP-1020-2HC-AT

42ton Automatic vulcanization forming press machine MODEL SDOP-1042-2H-AT

4-stage 42ton automatic vulcanization forming press machine MODEL SDOP-1042-8H-AT

Heating / Cooling 2-stage 42ton automatic vulcanization forming press machine MODEL SDOP-1042-2HC-AT

Full Automatic 4-stage 42ton forming press machine MODEL SDOP-1042IV-8H-FAT

Feature

Vertical transfer forming machine (2-head type automatic injection forming machine) Vertical transfer forming machine MODEL SDOP-1004PT-SD

Heating / Cooling 42ton automatic forming press machine MODEL SDOP-1042IV-2HC-AT

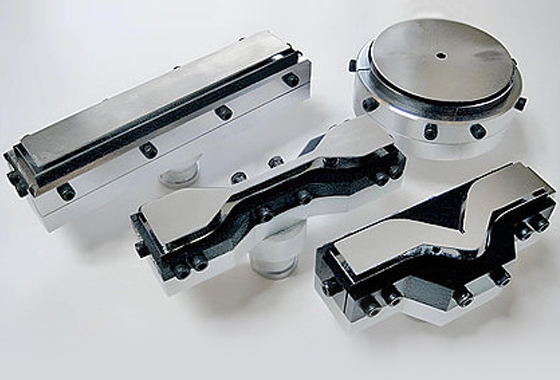

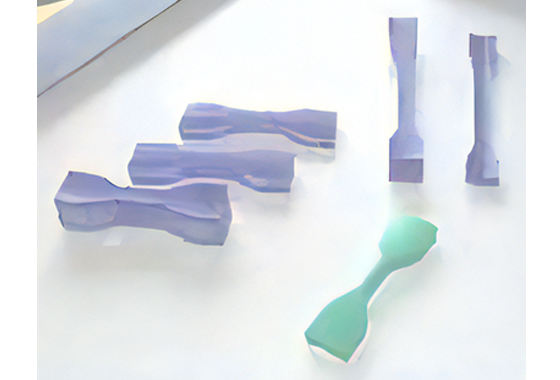

Light Weight Slab Forming Mold

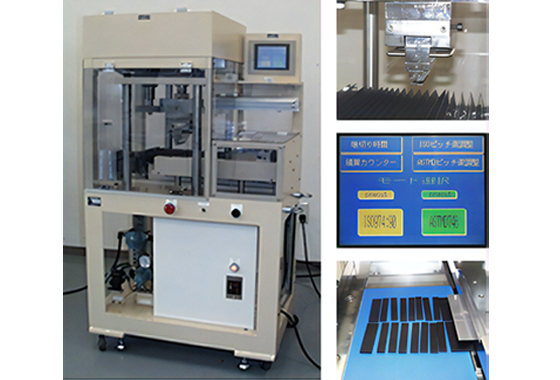

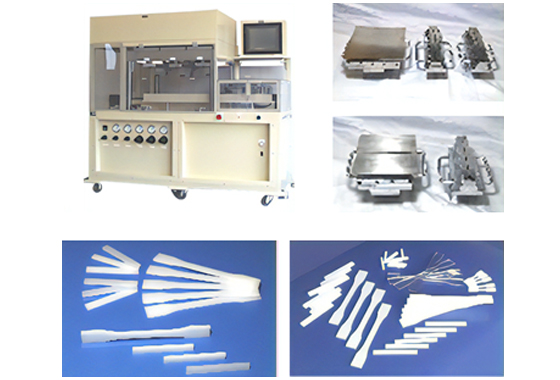

Brittleness temperature test specimen automatic cutting machine SDAP-1160FAT-PT

Dimension of Brittleness temperature test specimen stipulated by ISO 974/JIS standard is extremely microscopic size and strict allowable accuracy is defined. Also, numbers of test specimen to be put on the clamp are many [1 shot = 15 pcs. x numbers of brittleness destroy temperature point].

Therefore, it is necessary to make a large quantity of test specimen.

From this point of view, the biggest problem to be solved was to shorten the necessary time for making the test specimen and to obtain more accurate test specimen.

This cutting machine was developed to satisfy these purposes completely.

In addition, this cutting machine is combined with manufacturing function to make other various kinds of test specimen. Therefore, this is multi-functioning type automatic cutting machine which can be used for wide ranges.

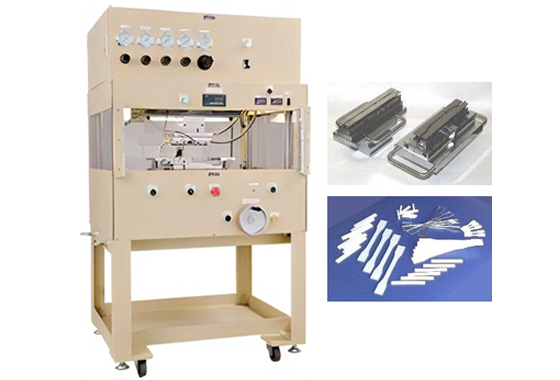

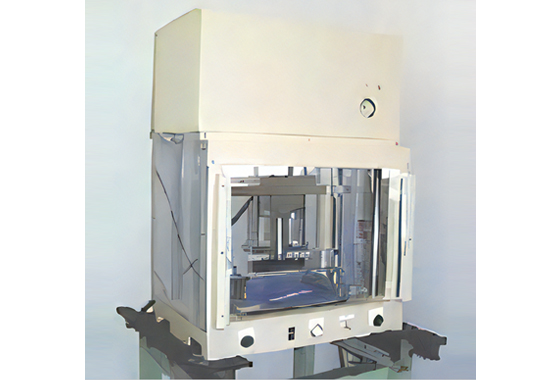

Plastic almighty test specimen cutting machine SDAP-1200FD-TRPL

Plastic full automatic test specimen cutting machine【Patent pending】SDAP-1183FBAT-PT

New type full automatic slab sheet cutting machine ATAP-1000N

Compressed air unvulcanized rubber cutting machine【Patent pending】 SDAP-1200FBGK

Desk type compressed air sample cutting machine (Prepared for pipes) SDAP-100NP

Desk type compressed air sample cutting machine SDAP-100N

Feature

1、Designed compact (Desk type).

Under head type compressed air sample cutting machine SDAP-1200FBR / SDAP-1200FDR

Nuogu Technology (Shanghai) Co., Ltd

TEL:

PHONE:+86 134 8256 0369

EMAIL:liudeqiang@nuogutech.cn

ADDRESS:Room 802, Building 6, No. 258 Songmin Road, Songjiang District, Shanghai, China, Postal Code: 2016111

Message

Scan the qr code to follow WeChat

Copyright ©Nuogu Technology (Shanghai) Co., Ltd 沪ICP备案123456号 technology:mingxi network 360导航